REBRAKE refurbishment brake service

NEW SERVICE ALERT!!

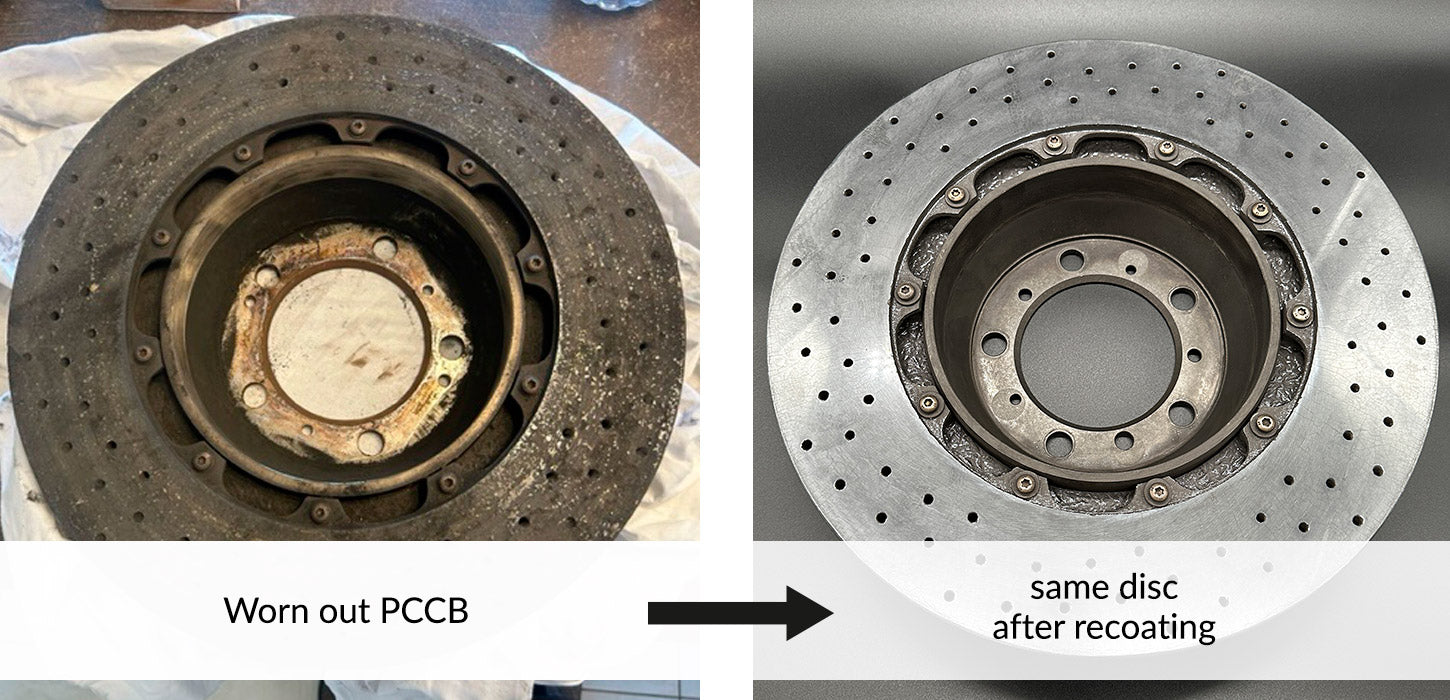

AutoCouture Motoring is excited to announce a new service designed to refurbish carbon ceramic brake disks rather than replace them, helping to save you thousands of dollars. When late model sports cars need brake service, the most expensive product is the carbon ceramic brake disks, but they are often not what gets damaged. Rather than replacing the undamaged rotors, this refurbishment service rebuilds the friction layer between the brake pads and the rotor.

In a simple and quick four step process, the new REBRAKE Friction Layer will restore the thickness and braking capability of the CCB to OEM specification at a fraction of the cost. In addition to restoring the friction layer, this service can repair the tiny imperfections to the worn brake rotors in one to two weeks.

Rotor edge damage can be effectively repaired by filling the rotor edge with material which is then bonded to the rotor during the baking process. Although minor repair to the rotor edge damage is provided at an additional cost, the overall process is still cost efficient when compared to purchasing a new OEM Rotor.

HOW ITS DONE:

The REBRAKE refurbishment brake service is completed in a quick 4-step process:

Step 1 →

After initial inspection, the worn rotors and the brake bell are separated, weighed, x-rayed, and assessed to determine the level of wear and structural damage that has occurred.

Step 2 →

The rotor surface is cleaned in a high-pressure blasting process to remove brake lining residues and impurities. This is done to prepare the surface for coating

Step 3 →

This is where the tiny imperfections to the worn brake rotors are repaired through a reconditioning phase with a high-tech process. The new friction layer is made of the combination of liquid silicification and a high-temperature oven bonding the friction layer and the brake rotor support structure to ensure excellent adhesion and a wear-resistant outcome.

Step 4 →

Grinding and polishing of the surface is conducted to an accuracy of 1/100 mm. The rotor is checked again, weighed, and balanced for final delivery. The brake rotor now has a new friction layer, is back to the original dimension in terms of thickness and diameter and has the target weight specified by the manufacturer.

Contact our team today to find out more about this exciting new service! Reach out to our shop to set up an appointment or give us a call at (201) 666-3500.

“You can’t buy cool; it must be built!”